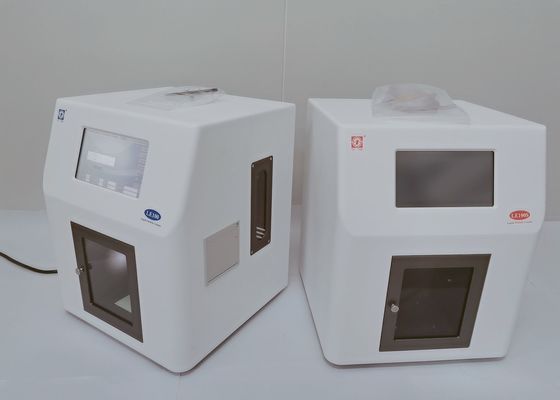

5ml Automatic Particle Counter For Filtration Efficiency Detection

5ml Automatic Particle Counter For Filtration Efficiency Detection

| Brand Name: | SUJING |

| Model Number: | LE100 |

| MOQ: | 1 |

| Price: | Negotiable |

| Payment Terms: | T/T |

| Supply Ability: | 800/per month |

5ml automatic particle counter

,60HZ automatic particle counter

,ptfe sensor liquid particle counter

LE100 Liquid Particle Counter Filtration Efficiency Detection

Our Liquid Particle Counters have the lowest false count rate, and are focused on true sensitivity.

| Technical parameters | liquid particle counter |

| Particle size range | 2-400 μm |

| Particle size channel | 24 |

| Maximum detection concentration | 10000 particles/ml |

| Accuracy | ±10% |

| Repeatability | RSD<2% (particles>1000 per ml, 5ml sample) |

| Resolution | <10% (U.S.P, ISO 21501) |

| Syringe specifications | 1ml, 5ml, 10ml*, 25ml |

| Sampling speed | 20 ml/min* |

| Sample volume accuracy | ±1% |

| Minimum sampling volume | 0.2ml** |

| Sensor material | 316 stainless steel, quartz glass, PTFE, NBR |

| Power supply | AC 100~240V, 50/60HZ |

| Mixing method | Magnetic stirrer (speed adjustable) |

| Data output | RS232 port; USB; built-in thermal printer |

| Display output | 7 inch LCD color touch screen |

| Size | 320(L)×309(W)×394(H) mm |

| Weight | 11.0 kg |

| Operating environment | Temperature 10-40 ℃; RH 0 ~ 95% non-condensing |

| Software system | LE-Assistant (optional) |

|

* Standard configuration ** Under 1ml syringe specifications the minimum sampling volume is 0.2ml, under the standard configuration, the minimum sampling volume is 0.4ml |

|

| 8.Exhaust fan | 1. Display |

| 9.heat emission hole | 2. Door of sample chamber |

| 10. Power switch | 3. Thermal printer |

| 11. AC power outlet and fuse | 4. Syringe |

| 12. R232 port | 5. Sample tube |

| 13. Sample drain | 6. LED chamber light |

| 14. USB port | 7. Stirrer |

Components of liquid particle counter

| The instrument ×1 | Power cord ×1 |

| Fuse ×1 | Detecting cup ×1 |

| Stir rod ×1 | Operation manual ×1 |

| Drain line tube ×1 | Testing report ×1 |

| Touch pen ×1 | Quality certificate ×1 |

| Printing paper ×1 | Warranty card ×1 |

| Packing list ×1 |

Application of liquid particle counter

-

Injections testing under CP, USP, EP, JP and other standards -

Cleanliness detecting of medical equipment / parts -

Filtration efficiency detection -

Laboratory water testing

![]()